- Home

- services

Services

Services We offer

Hartsgrove Machine Inc. specializes in high-quality machining solutions, which are the following:

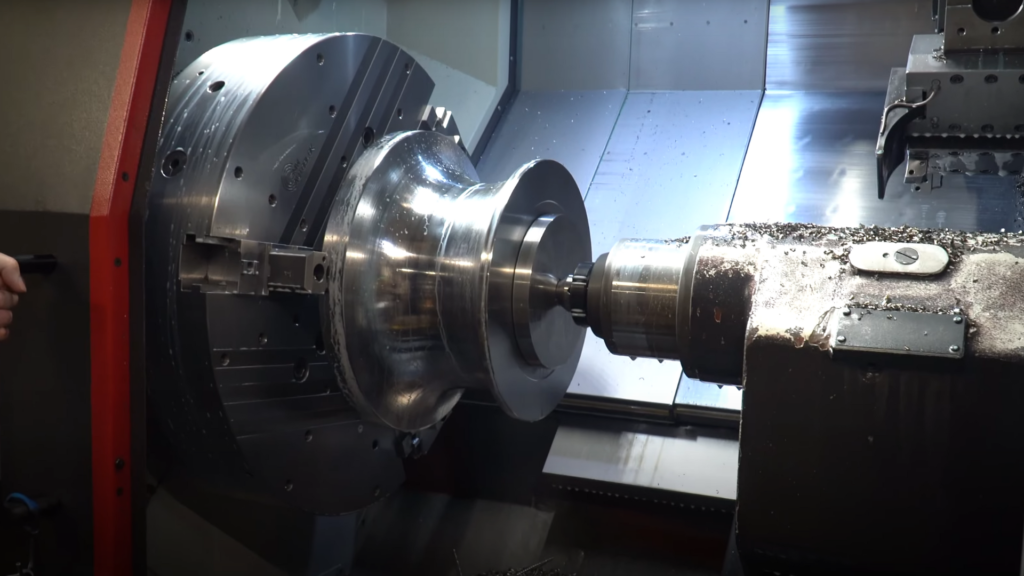

CNC Turning

With the capability to turn parts up to 31" in diameter and 21' in length, Hartsgrove Machine Inc. provides essential components such as large-diameter roll tools, mandrels, and dies used in both roll-forming and tube-and-pipe manufacturing. The ability to finish-turn hardened tool steel, including tungsten carbide, ensures these components maintain their precision and resist wear over extended production cycles. For roll forming, this supports accurate material shaping for profiles like structural beams or roofing panels, while in tube and pipe, it ensures consistent roundness and wall thickness critical for high-pressure pipelines or automotive exhaust systems.

CNC Milling

Our milling capabilities for parts up to 40" long x 20" wide x 20" high enable the production of intricate components like spacer blocks, side plates, and forming dies. For roll-forming operations, these tools are essential for achieving complex profiles such as decorative trims or solar panel mounts. In pipe-and-tube manufacturing, milled components support precise forming, bending, and cutting operations, ensuring tubes meet exacting standards for industries like HVAC, energy, or medical equipment. Various work-holding options further optimize tight-tolerance machining, allowing for flexibility in design and application.

CNC ROTARY SURFACE GRINDING

Blanchard grinding (up to 36" OD) and vertical grinding (up to 30" OD x 30" long) provide the precise surface finishes required for roll tools, mandrels, and forming dies in both industries. For roll forming, this ensures smooth material handling and consistent part profiles, reducing wear and improving the quality of components like wall panels or steel framing. In tube and pipe production, it guarantees dimensional accuracy and durability for tooling used in high-speed manufacturing environments, ensuring smooth and defect-free tubing.

Wire EDM

Our Wire EDM capabilities for parts up to 15" high are critical for creating detailed and precise tooling components such as cutting dies, intricate forming rolls, and inserts. For roll forming, this precision enables the production of sharp, clean profiles essential for applications like automotive trim or architectural components. In tube and pipe, it supports the creation of tooling that ensures precise cuts and complex geometries, crucial for specialty tubing in industries like aerospace or medical technology. Wire EDM provides the precision needed to minimize waste and optimize performance.

Engineering

Hartsgrove Machine Inc.’s engineering expertise, using AUTOCAD, SolidWorks, and Copra design software, supports the creation of custom tooling for both roll-forming and tube-and-pipe applications. For roll forming, our designs enable the production of complex profiles, reverse engineering of existing tools, and optimization for efficiency and durability. For tube and pipe manufacturing, we create specialized tooling to produce high-quality pipes with consistent diameters, wall thicknesses, and shapes. This engineering precision allows manufacturers in both industries to meet the demands of unique applications, from renewable energy projects to heavy-duty infrastructure.

Programming

Advanced programming capabilities, including MASTERCAM and conversational programming, ensure precision and efficiency in machining tooling for both roll-forming and tube-and-pipe production. This allows for the creation of complex geometries and tight tolerances required for high-speed manufacturing. Roll-forming clients benefit from tooling that supports multi-pass forming for intricate profiles, while tube-and-pipe manufacturers rely on our tooling for seamless bends, cuts, and forms. Efficient programming reduces lead times and enhances production reliability across both industries.

Profile Grinding

Profile Grinding is a precision machining process used to create highly accurate, complex shapes with tight tolerances. Utilizing the Amada GLS-150 optical profile grinder, we achieve superior surface finishes and intricate geometries, ensuring optimal performance for tooling and industrial components.